Ai-DTCO and Specialty IP

Background

IC manufacturing technology continues to evolve. Over the past few decades, the feature size of devices has shrunk by nearly a thousand times (10-6 m to 10-9 m). MOS structure has evolved from planar, fin-type (FINFET) to gate-all-around (GAA). The manufacturing process and design rules have rapidly increased from dozens to thousands. In the meantime, the scale of IC has also increased from thousands to billions and tens of billions of transistors. To adapt the huge chip design and complex manufacturing process to maximize the performance with the minimum area and power consumption (Design Technology Co-optimization DTCO) is a major point for IC design and production companies. This technology is based on artificial intelligence, collaboratively analyzes the characteristics of circuits and process technologies, and uses artificial intelligence to automatically generate the IP that best fits both the circuit design and technology to provide IC industrial the optimal DTCO solution and further provides special cell IP required to conquer barrier such as high-performance computing, high reliability and ultra-low power application.

Innovation

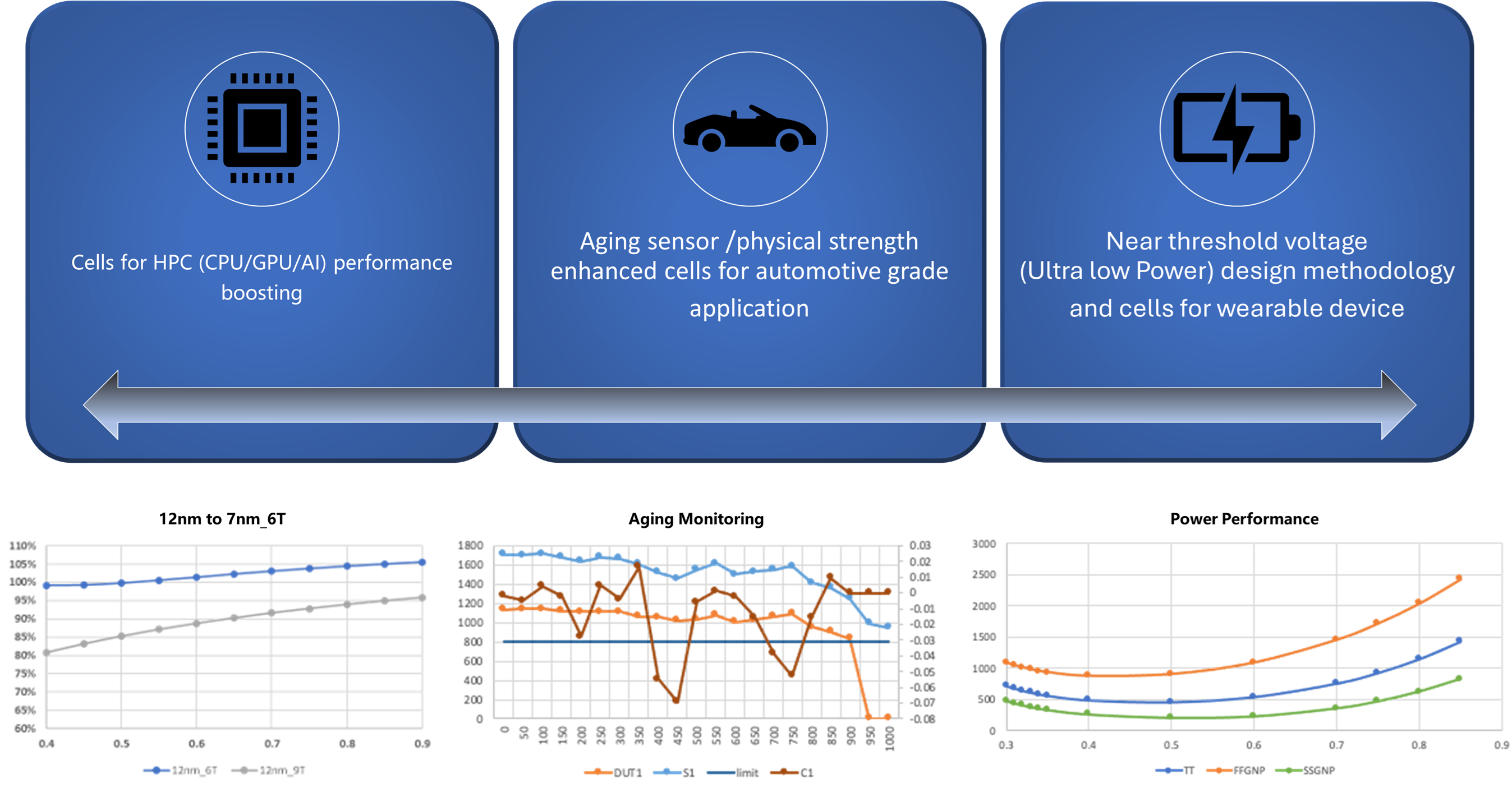

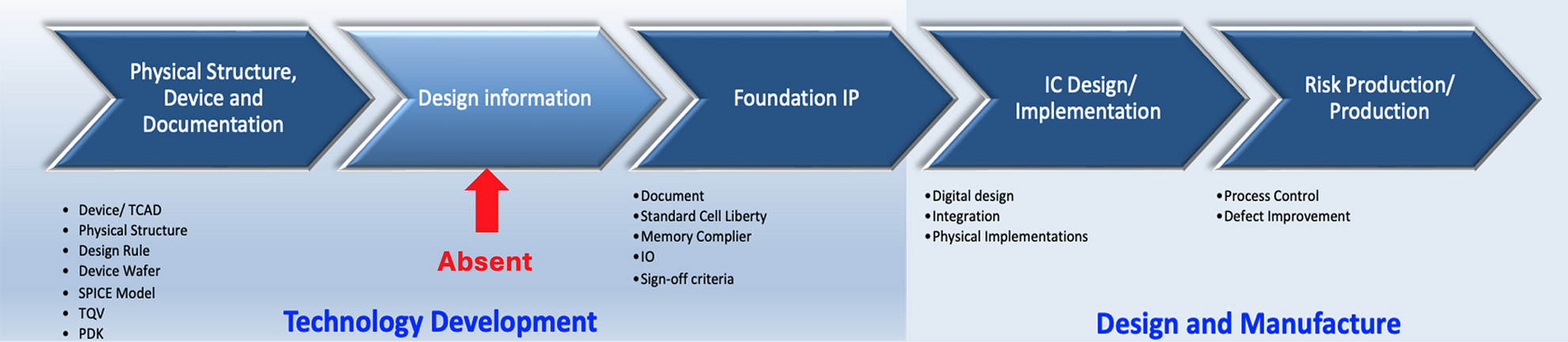

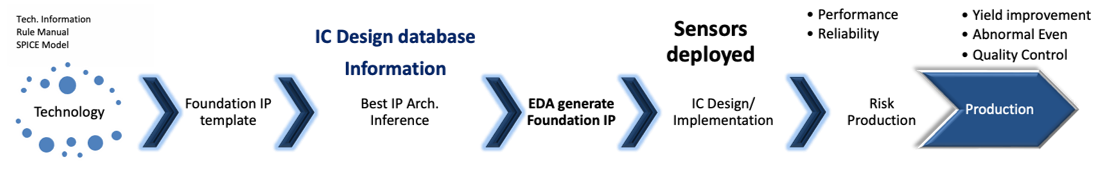

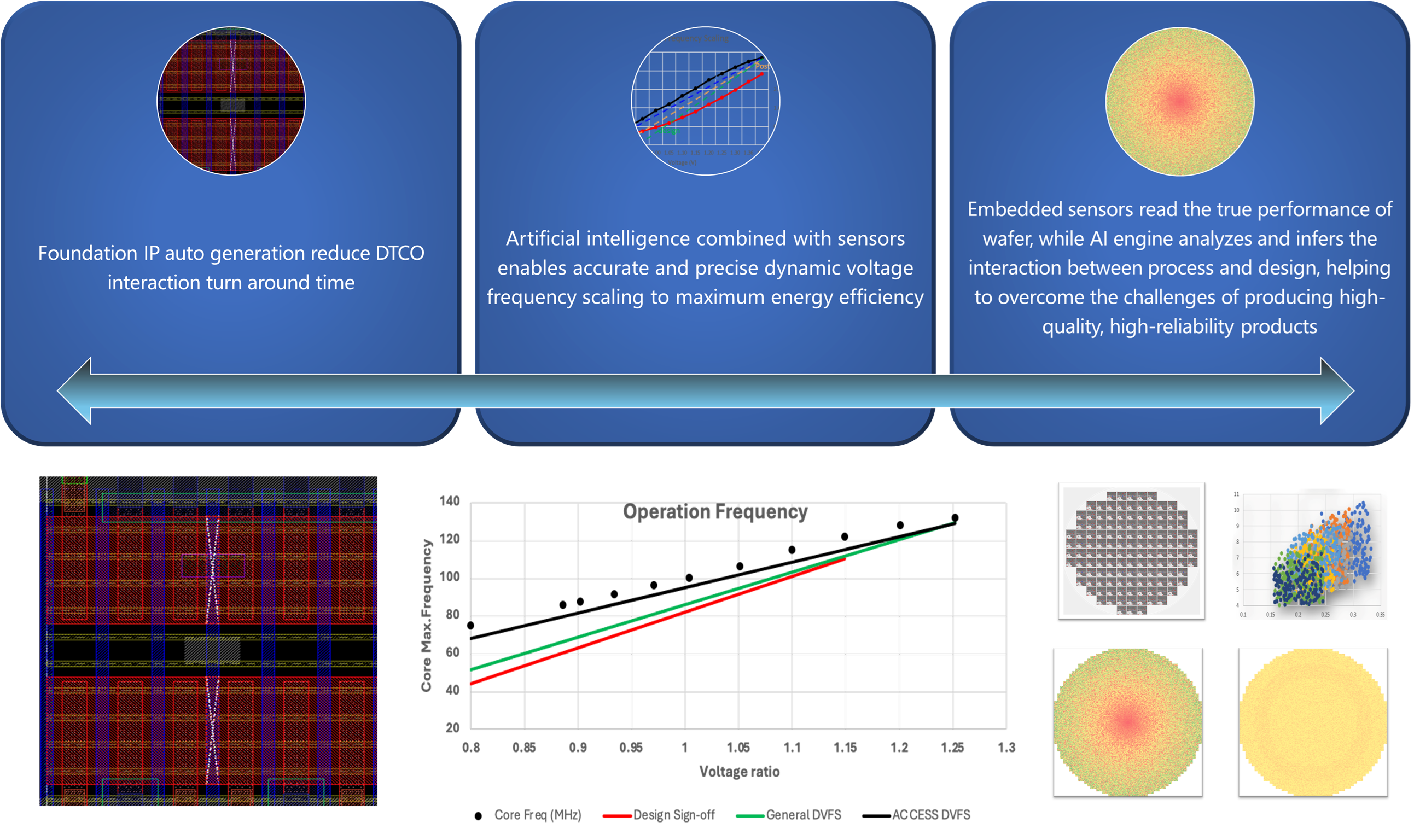

This project is based on artificial intelligence. It import chip design data even in the technology development stage, collaboratively analyze the characteristics of circuits and process technologies, and automatically generate the foundation IP that best matches the circuit design and technology. Artificial intelligence system predict the most suitable foundation IP architecture and index which best fit integrated circuit design and manufacturing process. Then an AI based tool generate a set of optimal cell IP. It also provides special cell IP required to conquer barrier such as high-performance computing, high reliability and ultra-low power application.

In addition, using artificial intelligence model to blend manufacturing processes and integrated circuit design then automatically generate cell IP required for general applications, high performance computing, high reliability and ultra-low power application, this project is also committed to solving the problem of deviations in the process flow at each stage of the production process, which gradually accumulates errors and causes the electrical characteristics of device to drift (Variation). Various sensors embedded in the chip are used to measure the circuit characteristics of the finished integrated circuit manufacturing products and various performance phenomena which result from the integrated circuit design. With the help of artificial intelligence-based analysis tools, engineers are assisted in monitoring and judging problems, providing a basis for further optimizing the design, improving the process, and quality control.

Performance Boost

Integrated Circuit Health